3D bioprinting works very similarily to the average 3D printer where a 2D digital model layer-by-layer becomes a tangible 3D object. Several methods of bioprinting exist based on different technologies, but the typical bioprinting process has the following standard steps.

The first step is 3D imaging where a CT or MRI scan is taken to obtain precise dimensions of the tissue. This allows for the most exact fit of the tissues with the least amount of adjustment needed by the surgeon. Next is 3D modeling which is where a blueprint is generated using AutoCAD software that shows the intricate details layer-by-layer. Final fine adjustments can be made here as well for optimal avoidance of the transfer of any defects.

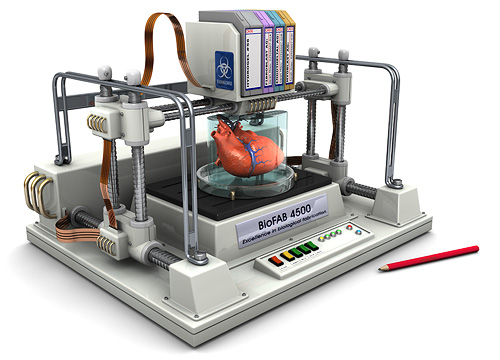

The third step is bioink preparation where a mixture is made of living cells and a compatible base such as silk, alginate, collagen, gelatin and many more based on the patient and the specific function of product. The fourth step is the actual 3D printing process by depositing the bioink in layers with a thickness of 0.5mm or less. The mixture will come out as a highly viscous fluid.

The final stage is solidification. During the phase deposition begins where the layer will begin as a viscous liquid and start solidifying to hold its shape. It will occur as more layers are deposited. The process of blending and solidification is called cross linking and is typically aided by a heat source (UV light, specific chemicals).

The process is in fact simple and quick which is why it makes it an efficient method.

Simply put:

- Step 1: Pre-bioprinting – the digital model that will be produced by the printer is created, uses computed tomography (CT) and magnetic resonance resonance imaging (MRI) scans

- Step 2: Bioprinting – the printing process, where bioink is put in the cartridge for deposition to occur based on the digital model

- Step 3: Post-bioprinting – the chemical and mechanical stimulation of the organ or tissue to balance the biomaterial occurs in which cells are inserted